The flotation tank is a common component in wastewater treatment systems. While solids can settle naturally by gravity, this process is time-consuming. The flotation tank accelerates the separation and removal of suspended solids, grease, and BOD from the liquid mixture, ensuring wastewater quality meets environmental standards.

Image 1. Actual image of a circular flotation tank.

I. What is a flotation tank DAF ?

vThe Dissolved Air Flotation (DAF) tank, also known as a super shallow flotation tank, is designed to separate and remove dissolved solids from liquids such as grease, suspended solids, and BOD. This process operates on the principle of pressure difference between two environments.

vThe flotation method is widely employed in wastewater treatment across various industries including mining, synthetic fiber manufacturing, paper manufacturing, machine building, seafood processing, food, and chemicals.

Related content: Superior agricultural floating selection equipment.

vIts tanks are classified based on various criteria including their shape, nature, operating mechanism, and connected external auxiliary equipment such as air compressors, pressure tanks, slurry rakes, pumps, etc…

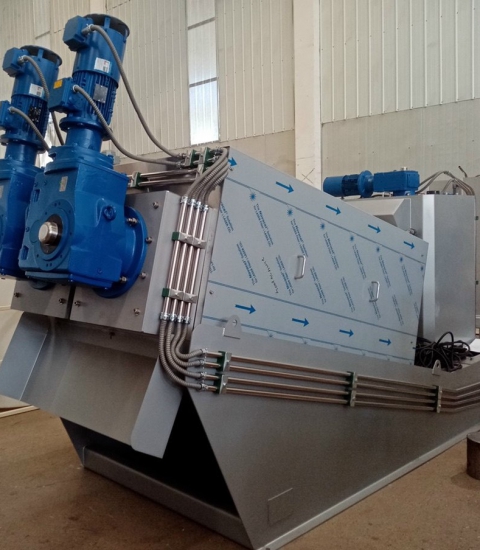

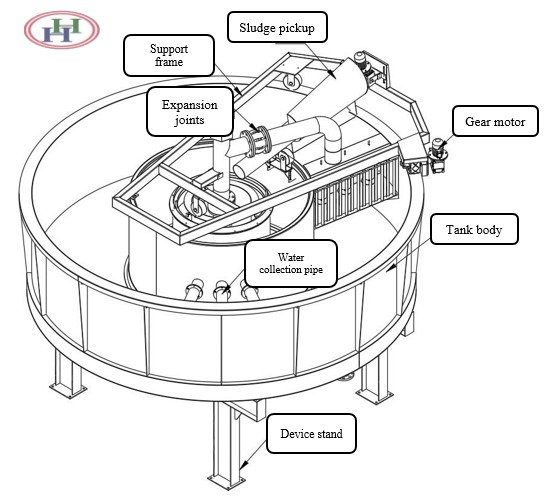

vStructure:

Container: Rectangular or square-shaped, made of stainless steel to prevent rust and corrosion.

Container support frame: Supports and secures the position of the container.

Engine support frame: Provides support for the sludge pickup and engine components.

Gear reduction motor: Controls the movement of the sludge pickup and determines rotation speed.

Sludge pickup ladle: Collects sludge from the surface and deposits it into the storage compartment.

Image 1.1 Flotation tank structure details.

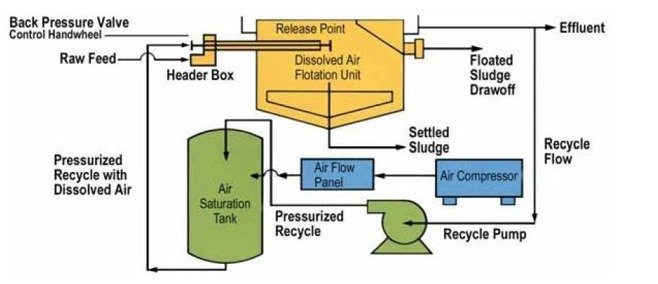

II. Flotation principle:

vFlotation tanks operate on the principle of density difference between sediment particles and water. When sediment particles have lower density than water, they float on the surface of the tank and are separated from the water. To enhance descaling efficiency, gas-saturated water at high pressure is often introduced. As this water enters the tank at lower pressure, it releases fine air bubbles. These bubbles adhere to sediment particles, increasing their buoyancy and thereby enhancing process efficiency.

vThe principle diagram of flotation tank:

Image 2.1 Flotation tank operation principle.

Operation:

Related content: Hong Ha - A reputable base providing high-quality rotary damper equipment.

Ø Wastewater containing sediment or grease (sludge) passes through the mixing compartment (stirring with a paddle can be used, or static stirring). Here, wastewater is supplemented with chemicals that coagulate before entering the partition.

Ø The amount of water returned, which is saturated with air at high presure (2 – 5 atm) through a pressure tank return pump and air compressor.

Ø When entering the sorting compartment, the released saturated gas particles adhere to the sludge that has been coagulated before, increasing the buoyancy speed of the sludge to help the process achieve high efficiency.

ØThe amount of sludge floating on the surface is pushed into the sludge collector by the floating sludge system and then pumped to the sludge storage tank (usually the common sludge tank of other stages in the same treatment line) and dried before disposal.

Ø The amount of clear water colleted through the spillway wall to the storage tank (or subsequent treatment stages).

Ø Each part of the sludge that is settled to the bottom is periodically removed by a sludge pump. The bottom of the tank can be fitted with a flocculant system or made a sloping bottom to collect sediment.

Image 2.2 Flotation tank products of Hong Ha Environmental Mechanic Company.

III. The role of the flotation tank:

Related content: Garbage separator - Useful device for garbage removal.

vThe flotation system is designed for integration and full automation, allowing it to operate independently or be integrated into a processing system.

vThe tank's versatility allows it to be used across various industries for effectively separating solid particles and liquids, including industrial wastewater treatment, fisheries, water supply, textiles, food processing, swimming pools, power generation technologies, etc…

vAdditionally, the tank serves multiple purposes depending on its placement within the system. In some setups, flotation tanks are positioned at the initial stage to remove fats, grease, and suspended solids from wastewater, optimizing system efficiency and reducing the load on downstream equipment. In other configurations, tanks are installed after biological treatment to further reduce pollutant loads and stabilize pollutant concentrations. Alternatively, tanks may be placed at the end of the system to reduce turbidity, ensuring water quality meets environmental discharge standards or facilitating water reuse requirements.

Image 3.1 Actual images of the flotation tank seen from a distance.

vWater and sludge reuse: after removing pollutants, wastewater undergoes further treatment to produce clean water. The resulting sludge, with its low moisture content, can be reused to reclaim production materials in industries such as paper, rubber, textiles, starch, and animal food processing. Recovering valuable products from wastewater not only facilitates capital circulation for businesses but also reduces industrial waste discharged into the environment. This promotes the development of a green, sustainable, and environmentally friendly industry that benefits humanity.

Related content: Sluice gate - Flow control device.

Image 3.2 Actual images of a rectangular flotation tank.

vReduce air pollution: Flotation helps reduce air pollution by removing volatile organic substances and minimizing odors from wastewater. This protection enhances air quality and environmental conditions around wastewater treatment facilities.

vThe equipment helps to enhance the efficiency of wastewater treatment before water is discharged into the environment, ensuring cleanliness and safety for human health, contributing to improving water quality and protecting the environment, especially in coastal areas, riversides and groundwater extraction areas.

vOil & Gas Industry: DAF tanks are applied in oil refining, wastewater treatment from refineries, chemical plants and oil extraction operations. It helps remove oil particles, dirt and other pollutants from the water.

vRemoval of hazadous substances: Flotation technology can be used to remove toxic substances such as heavy metals, pesticides and other contaminants present in wastewater. These substances are separated using flotation particles coated with a special layer of active ingredients.

Image 3.3 Actual images of the flotation tank seen from above.

Image 3.4 Production of flotation tank at the factory of Hong Ha Enviromental Mechanic Company.

Image 3.5 Flotation tank at the factory of Hong Ha Enviromental Mechanic Company.

ÄSummary: Flotation tanks (DAF) are wastewater treatment equipment widely utilized across industries and municipal wastewater treatment due to their high efficiency. They occupy minimal space but demand rigorous technical expertise for operation and maintenance. Despite these requirements, flotation tanks are preferred by businesses for their exceptional ability to treat pollutants effectively.

Hong Ha company guarantee:

Hong Ha boasts years of experience in designing, fabricating, and producing environmental mechanical products, ensuring high-quality, durable, and aesthetically appealing solutions. Our commitment includes:

Competitive pricing as a direct manufacturer and distributor, offering quality-assured products to reduce investment costs for customers.

Diverse designs and sizes to meet various customer needs.

Comprehensive services including transportation, on - site installation, and ongoing technical support.

A professional consulting team ready to handle any situation and provide optimal solutions.

Dedication to meeting customer requirements and maintaining high-quality standards.

State-of-the-art equipment and machinery ensuring precise production and quality control.

Tailored equipment design based on each project's specific requirements.

A trusted partner of numerous domestic, international companies, reaffirming our reputation.

Conclusion:

Hong Ha Company takes pride in being the preferred choice of domestic and international customers. Our motto is to create high-quality, efficient, and cost-effective equipment to meet customer needs. When you choose Hong Ha, we guarantee top-quality products at competitive prices with exceptional service. We are committed to continuous improvement and delivering effective solutions tailored to our customers' requirements. Hong Ha looks forward to future collaborations to achieve optimal results for your needs.

For more information or to explore our range of flotation tanks and other environmental mechanical equipment, please feel free to contact us.

HONG HA ENVIROMENTAL MECHANIC COMPANY LIMITED

Address: No.15, Street 53, Ward 8, Hiep Binh Chanh District, Thu Duc Sub City, HCM City

Hotline: 028.5403.6126 – 0908.182.171

Email: inoxhongha@gmail.com

Website: cokhihongha.com.vn